This Japanese Company Uses XR to Make Manufacturing Experience 'Digitally Immortal'!

Manufacturing is facing a severe challenge: precious experience from veteran craftsmen has nowhere to be passed down, new workers are slow to get started, efficiency is low, and there are even serious safety hazards. This "skill transfer" gap is giving countless companies headaches. Imagine if you could "move" an entire factory into a virtual space, allowing everyone to learn and practice in an immersive environment, and even conduct real-time assessments—how cool would that be? This is no longer science fiction, but the "LegacyLink XR" platform that VR Design Laboratory Co., Ltd. is about to launch, using mixed reality (MR) and 3D Gaussian Splatting (3DGS) cutting-edge technology to reshape the future of manufacturing.

Farewell to Armchair Theory, Welcome to "Real Deal" Immersive Training

Traditional manufacturing training often stays at theoretical explanations and limited practice. Expensive equipment, dangerous operations, and limited space make efficient, repeated skill training a luxury. The emergence of the LegacyLink XR platform has completely broken these limitations. It doesn't just let you "see" knowledge but makes you "do" skills until you master them.

Black Tech Revealed: Three Core Advantages Making Skill Transfer Within Reach

LegacyLink XR can deliver such a disruptive experience thanks to three killer features:

"3D Gaussian Splatting (3DGS)" Technology. This isn't simple photo modeling. It can move real-world equipment and production lines into MR environments with unimaginable precision. Think about it—you put on an MR headset, and right before your eyes is identical machinery, every screw and component clearly visible. This high fidelity makes learners feel like they're in a real factory, with more immersive operations and better understanding of complex equipment's internal structure and working principles.

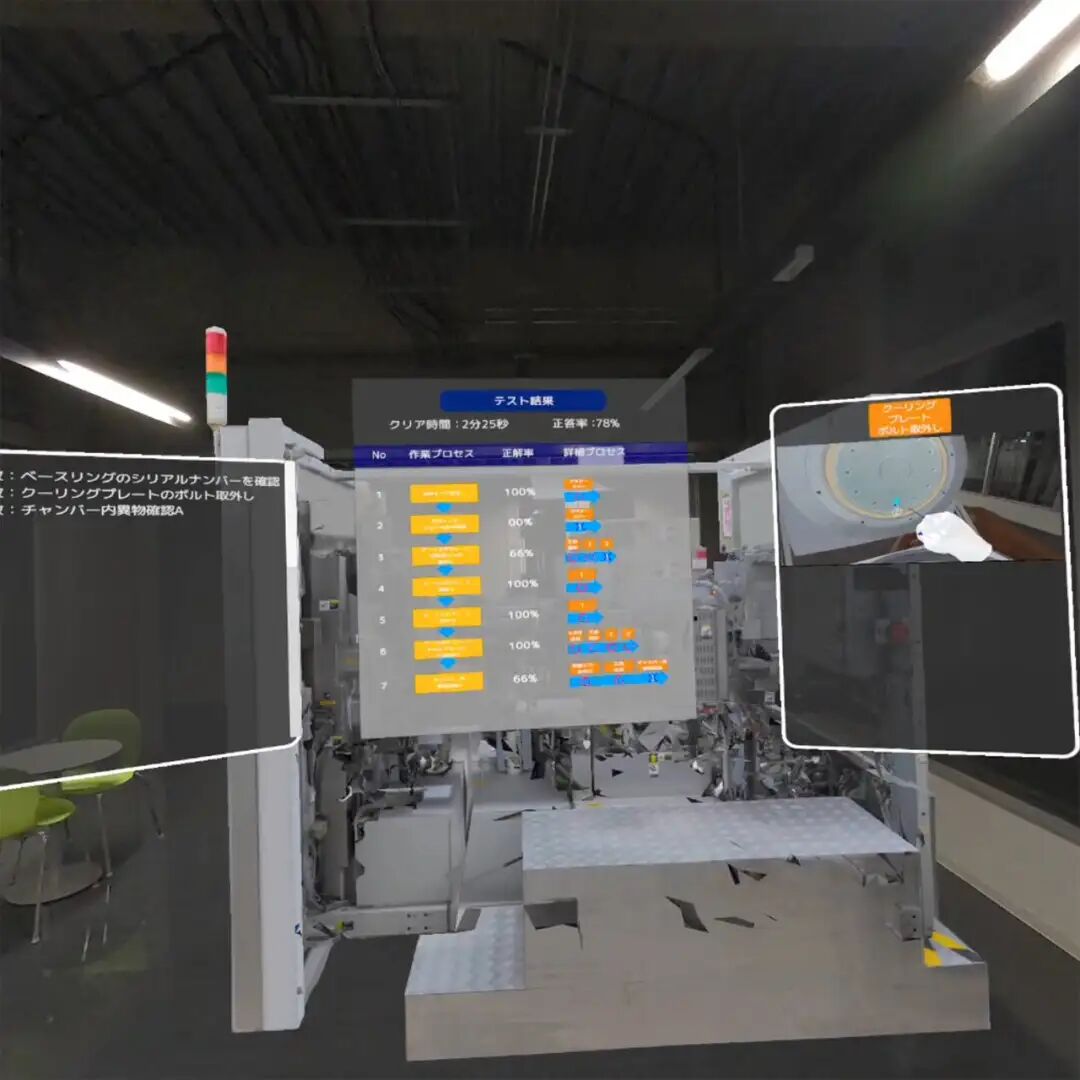

"Skill Assessment Mode"—this is the key to transforming skills from "knowing" to "doing." After learning, you can immediately take practical tests in this virtual environment. The system evaluates in real-time whether your operations are standard and steps are correct, capturing even subtle deviations with precision. Even better, it points out exactly where you went wrong and provides detailed explanations. This instant feedback and precise error correction is like "hand-in-hand" teaching, helping newcomers grow quickly and avoiding the awkwardness of traditional training where "you learn but can't apply." For managers, they can check each trainee's learning progress and assessment results through the cloud anytime, achieving refined skill evaluation and talent management.

And efficient "Collective Training Mode". In the past, one master craftsman teaching a few apprentices was already exhausting. Now, the LegacyLink XR platform allows one instructor to manage up to 50 trainees simultaneously. Instructors can monitor all trainees' operations in real-time through the main control interface, ensuring everyone keeps up with progress. Even more impressive, it can conduct large-scale training without network connection, which is a blessing for factory environments with poor network conditions. This not only significantly reduces training costs but also greatly improves training efficiency and coverage.

Empowering Future Factories: "Superpowers" Everywhere from Chips to Cars

LegacyLink XR's potential extends far beyond this. In the semiconductor industry, it can simulate precise chip assembly processes and dangerous chamber cleaning operations; in automotive manufacturing, complex assembly line operations, paint process quality control, and even automotive repair training can be repeatedly practiced in virtual worlds; in electronics production lines, precise circuit board soldering and electrostatic protection education can become vivid and interesting. Whether it's safety training for high-risk operations or standardized learning of high-precision processes, LegacyLink XR provides a safe, efficient, and reproducible training environment, helping every "warrior" on the production line quickly master skills and become true technical backbones.

Conclusion

The launch of the LegacyLink XR platform is not just another innovation from VR Design Laboratory but a profound transformation in manufacturing skill transfer. Using cutting-edge MR and 3DGS technology, it provides enterprises with an efficient, immersive, and quantifiable training solution, truly achieving the leap from "experience transfer" to "digital transfer." The future is here—when hyper-realistic technology combines with real production, we have reason to believe that manufacturing will usher in a more intelligent, efficient, and vibrant era. At the upcoming CEATEC 2025 exhibition, we'll also have the opportunity to glimpse its true nature and personally experience the charm of this technology.

Reference:

https://prtimes.jp/main/html/rd/p/000000020.000021662.html

分享文章

3篇相关文章

Farewell And Rebirth: As WebAR Giant 8th Wall Exits, Where Do We Go Next?

2025-11-26

WebAR platform 8th Wall is shutting down and considering open‑sourcing its core. This marks a major shift for XR—and a wave of new opportunities and challenges.

A New XR Education Era: How Samsung Galaxy XR Reinvents Enterprise Training

2025-11-14

Samsung Human Resources Development Institute adopts Galaxy XR, fusing AI with extended reality to redefine corporate learning.

South Korea XR Stuns the World: From Digital Healing to AI Collaboration, Unveiling Eight Pioneers of Future Digital Life

2025-11-03

South Korea's innovation wave in XR, metaverse, and AI is sweeping the globe. This article explores eight Korean pioneers reshaping digital life through cutting-edge tech—from physical and mental wellness to entertainment, smart operations to artistic creation—showcasing the vibrant energy and infinite possibilities of Korea's digital content industry.